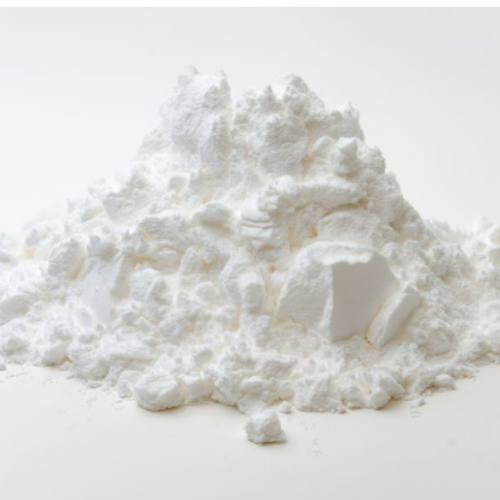

High Opacity and Versatility

R-215 is designed for formulators searching for a single grade of Tio2 with performance covering a wide range of water-based paint,solvent-based paint, powder coating, printing ink, and papermaking

Typical Properties

Processing Method | Sulfate |

Crystal Form | Rutile |

Inorganic Surface Treatment | SiO2, Al2O3 |

Organic Surface Treatment | Yes |

ISO591-1 Classification | R2 |

Relative Scattering Power(ISO 787-24) | 95%-105% |

Color(ISO 787-25) | △E≤0.5 |

Density(ISO 787-10) | 4.0g/cm |

Dispersion in Polyester System(GB/T 21868.3-2008) | ≤35μm |

Key Features

◆ Neutral undertone

◆ Easy wetting and dispersing

◆ High tinting strength and opacity

◆ Moderate gloss

Typical Data

TiO2 Content(ISO 591-1) | 92% |

CIE L * ( GB / T 1864-2012) | 95 |

Reducing Power ( TCS ) | 2000 |

PH Value(ISO 787-9) | 7.2 |

Oil Absorption(ISO 787-5) | 20g/100g |

Residue on 45μm(ISO 787-18) | 0.01% |

Resistivity(ISO 787-14) | 100Ω·m |

Volatiles at 105℃(ISO 787-2) at packaging | 0.4% |

Subject to measurements in COA

Health and Safety Precautions

Relevant local health and safety guidelines should be followed. Gloves safety goggles and respirators with submicron particle filtration should be worn. MSDS is available upon request.

Packaging

R-215 is available in 25kg bags, 500kg and 1000kg containers.

Product Storage

Store the product indoors in clean and dry conditions. The shelf life of CHTi’s TIO2 is 2 years if stored properly.

The first-in-first-out regime is highly recommended to ensure the performance of the product.

Applications of Titanium Dioxide(CAS 13463-67-7)

Application of titanium dioxide in the coating industry

In all applications of pigment titanium dioxide, the amount of coating is the largest. Titanium dioxide is widely used in coatings, such as buildings, automobiles, ships, furniture, household appliances, coil coating, toys and daily necessities. In the coating industry, architectural coatings consume the most titanium dioxide, followed by coatings for automobiles, ships, railway vehicles and furniture. Because rutile titanium dioxide has better performance than anatase titanium dioxide, rutile titanium dioxide is selected as high weatherability coating for outdoor use of ships, bridges, automobiles, buildings and so on. At present, rutile titanium dioxide has exceeded that of titanium dioxide used in coatings. With the development of China's automobile industry and construction industry, the coating industry not only needs more titanium dioxide in quantity, but also has higher requirements for variety and quality.

Application of titanium dioxide in the papermaking industry

Titanium dioxide is mainly used as filler in the paper industry. Titanium dioxide for papermaking generally uses anatase titanium dioxide without surface treatment, which can play the role of fluorescent brightener and increase the whiteness of the paper. However, the laminated paper requires the use of rutile titanium dioxide with a surface treatment to meet the requirements of light resistance and heat resistance. Because titanium dioxide has a high refractive index and achromatic power, adding titanium dioxide to the pulp can make the paper have better whiteness, higher opacity, good gloss, high strength, thin and smooth, nonpenetration during printing, and lightweight.

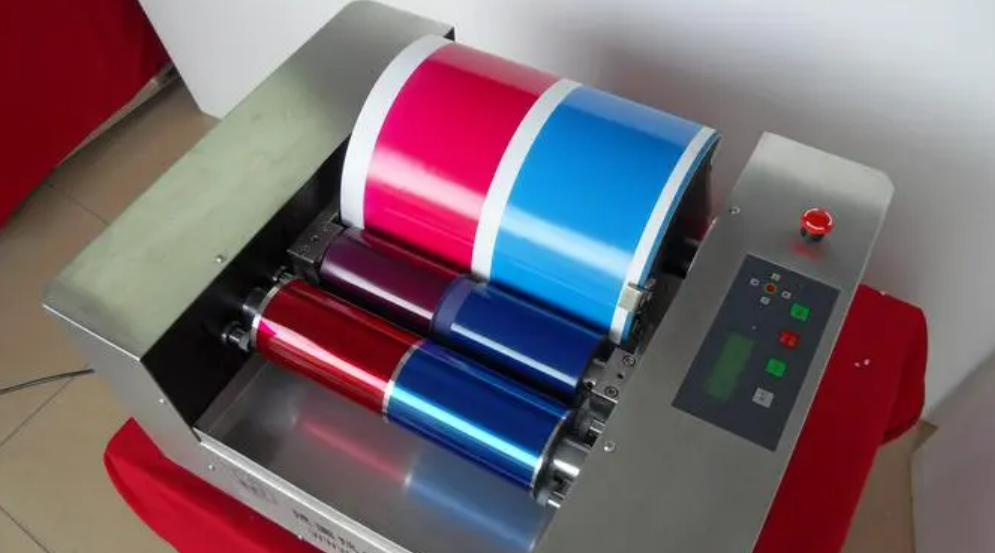

Application of titanium dioxide in the ink industry

Titanium dioxide has the characteristics of good whiteness, small and uniform particle size, high refractive index, high coloring power and hiding power, good physical and chemical stability, light diffusion, light resistance, heat resistance, weather resistance and hydrophobicity, which make titania not only an indispensable white pigment in ink manufacturing, but also a necessary raw material for blending many intermediate color ink products. The ink containing titanium dioxide is durable, does not change color, has good surface wettability, and is easy to disperse. Titania used in the ink industry has rutile type and anatase type.

Titanium dioxide is an important inorganic chemical pigment, which is mainly composed of titanium dioxide. It has important applications in coatings, ink, paper, plastic, rubber, chemical fiber, ceramics and other industries. Titanium dioxide is not only used as colorant in rubber industry, but also has the function of reinforcing, anti-aging and filling. Titanium dioxide is added into white and color rubber products. Under sunlight, it is resistant to sunlight, cracking, discoloration, high elongation and acid-base resistance. Titanium dioxide for rubber, mainly used in automobile tires and rubber shoes, rubber floor, gloves, sports equipment, etc., is mainly anatase. However, a certain amount of rutile products are often added in the production of automobile tires to enhance the ability of anti ozone and anti ultraviolet. Titanium dioxide is widely used in cosmetics. Because titanium dioxide is nontoxic and far superior to lead white, almost all kinds of perfumes use titanium dioxide to replace lead white and zinc white. Only 5% - 8% titanium dioxide can be added to the fragrance powder to get permanent white, which makes the fragrance more greasy and has adhesion, absorption and covering power. In gouache and cold cream, titanium dioxide can reduce the feeling of greasy and transparent. Titanium dioxide can also be used in other spices, sunscreen, soap tablets, white soap and toothpaste.