Anhui, China

Anhui, China

Anhui, China

Anhui, China

Send Email

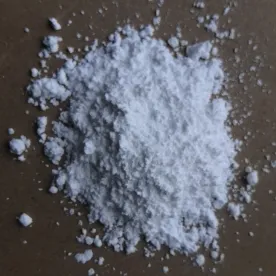

Microcrystalline Cellulose / CAS 9004-34-6

OVERVIEW

Uses

Packaging

20 KG/Woven Bag

Lead Time

14-30 days

Max Capacity

6730 MT/Year

REQUEST A QUOTATION

SubmitDESCRIPTION

Microcrystalline cellulose

This product is made from cellulose plant fiber pulp α- Cellulose is partially depolymerized and purified under the action of inorganic acid. The properties are white or almost white powder or granular powder; Odorless and tasteless. It is almost insoluble in water, ethanol, ether, dilute sulfuric acid or 5% sodium hydroxide solution.

purpose

This product has the functions of shaping, bonding, water absorption and expansion. It can be used as tablet adhesive, diluent, disintegrating agent and flow aid, and the dosage is generally 5% - 20%. It can be used not only for wet granulation, but also for direct tablet pressing, but also as capsule diluent, and the dosage is generally 10% - 45%.

Storage

Sealed storage.

packing

20kg / bag

Executive standard

CP、USP、BP

model | granularity | water content | Application guidance |

SH-CG1 | 50um | -- | It is mainly used as adhesive,disintegrating agent and filler in oral tablets,capsules, granules, pills and other dosage forms, and is suitable for wet granulation. |

SH-101 | 50um | -- | It is the most widely used auxiliary material in wet granulation. It is widely used in blank pill core, extrusion rolling pills and pellets. It can be used as an adhesive. It is suitable for oral solid preparations with loose materials, can improve the hardness of tablets, and can also be used for direct tablet pressing. |

SH-102 | 90um | -- | It has a large particle size, can effectively improve the fluidity, and is suitable for direct tablet pressing of all powder. |

SH-103 | 50um | ≤3% | It is mainly used in drug dosage forms with large active components and sensitive to water. |

SH-105 | 30um | -- | The particle size is small and has very good compressibility. It is suitable for mixing small particle size materials and materials with low active ingredient content to improve the content uniformity. It is used for direct tablet pressing of tablets and crystal particles with high hardness requirements. |

SH-112 | 90um | ≤3% | Low moisture, good fluidity, suitable for drug dosage forms that are particularly sensitive to moisture, and suitable for direct tablet pressing of all powder. |

SH-200 | 180um | -- | Low moisture, good fluidity, suitable for drug dosage forms that are particularly sensitive to moisture, and suitable for direct tablet pressing of all powder. It has large particle size and can be used to increase fluidity. It can be used in direct tablet pressing prescription and (as the final mixed additive) wet granulation prescription to reduce weight change and improve content uniformity. |

SH-301 | 50um | -- | It has greater bulk density and better fluidity, which can increase fluidity, obtain more uniform sheet weight, have the potential to manufacture smaller sheets, and improve mixing characteristics. As a commonly used capsule filler. High density, fast flow, suitable for rapidly disintegrating tablets. |

SH-302 | 90um | -- | It has higher density, better fluidity and faster disintegration than 102. It is suitable for direct tablet pressing of all powder. |

SH-802 | 50um | -- | High performance auxiliary materials, good formability, less dosage, low fragility and good compressibility. Suitable for low pressure use. |

SH-12 | 150um | -- | Similar to 200, the particle size is slightly smaller and suitable for direct tablet pressing. |

Pellet core | -- | -- | It is mainly used as the carrier of enteric coated pellets and slow and controlled release pellets. |

Typical Properties

Food(Feed) Additives > Anticaking Agent

GET SAMPLE

Submit- Overview

- Descriptions

- Sample