Jiangsu, China

Jiangsu, China

Jiangsu, China

Jiangsu, China

Send Email

Cellulose Ether / CAS 9004-65-3

OVERVIEW

Packaging

25 KG/Woven Bag

Lead Time

14-30 days

Max Capacity

6000 MT/Year

REQUEST A QUOTATION

SubmitDESCRIPTION

Cellulose Ether

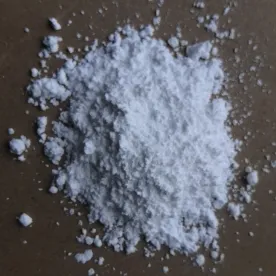

Cellulose Etheris a non-ionic cellulose ether made from the polymeric material cellulose by a series of chemical

processing. They are a type of white powder that swells into a clear or slightly turbid colloidal solution in cold water. Has properties such as thickening, bonding, dispersion, emulsification, film formation, suspension, adsorption, gel, surface activity, moisture retention and protecting colloids. Hydroxypropyl methylcellulose can be applied in the industries of building materials, coating industry, synthetic resins, ceramic industry, medicine, food, textile, agriculture, daily chemical and other industries.

Chemical equations:

Cellulose Ether(HPMC)[C6H7O2(OH)3-m-n(OCH3)m(OCH2CH(OH)CH3)n]x

Application areas:

● cement based mortar

1. Improving homogeneity makes the spread of mortar easy while improving the flow resistance ability. Enhance fluidity and pumping and thus work efficiency.

2. High water retention, prolonged the working time of the ash, improved the working efficiency, and contributed to the formation of high mechanical strength of the ash during the solidification period.

3. The infiltration of air was controlled, thus eliminating the micro cracks of the coating to form an ideal smooth surface.

● lightweight composite wallboard

1. Enhance workable properties of extruded lightweight wallboard with bond strength and lubricity.

2. Improving wet strength and adhesion after extrusion of plates.

● plaster plasters and plaster products

1. Improved homogeneity, which allowed easy spread of the mortar, along with increased resistance to sag flow enhancing fluidity and pumping. Thereby improving the work efficiency.

2. High water retention, prolonging the working time of the ash, and resulting mechanical strength upon solidification.

3. Excellent surface coatings were formed by controlling the consistency uniformity of the mortar.

● building mortar

1. Enhances adhesion to the surface of BMS and also enhances water retention, which allows mortar strength to be increased.

2. Improving lubricity and plasticity leading to improved construction performance, use of maciterol reinforced mortar, saving time, and improving cost-effectiveness.

● plate fillers

1. Water retention, which may prolong cooling time and increase work efficiency. High wettability, which makes application easy and smooth.

2. Improve the anti contractility and anti cracking properties, and improve the surface quality.

3. Provides a fine and uniform texture, and makes the bonding of the bonding surface strong.

● tile binder

1. Making the dry blended ingredients easy to mix, does not produce clumps and thus saves working time. As administration is rapid and effective, it improves constructability, and reduces costs.

2. By extending the cooling time, the patch efficiency was improved. Provide adhesive effects.

● water based coatings and paint removers

1. The storage period was extended by preventing the precipitation of solids. Compatible with other components and has high biostability.

2. Dissolution is rapid without clumping, helping to simplify the mixing process. Cold water dispersive model products that allow for more rapid and convenient mixing,

And no clumps are produced.

3. The flow characteristics, including low splash and planarity, are produced to ensure surface finish and stop paint drooping.

4. Enhancing the viscosity of water-based paint removers and organic solvent paint removers so that paint removers do not flow out of the workpiece surface.

● self flowing flat ground material

1. Provide viscosity and may act as an anti precipitation aid.

2. Enhance fluidity and pumping, thereby increasing the efficiency of plating.

3. Water retention is controlled, thereby reducing cracking and shrinking.

Packaging and storage precautions

The present article packs 25 kg of each net weight with a coated film plasticized pocket.

Avoid rain and rain when storing. Protection against moisture

Typical Properties

Auxiliary > Textile Auxiliaries

Food(Feed) Additives > Thickening Agent

GET SAMPLE

Submit- Overview

- Descriptions

- Sample