b

Thank You!

Your requirement has been sent, we will contact you quickly!

Sent Failed!

Try again!

What is battery aluminum foil?

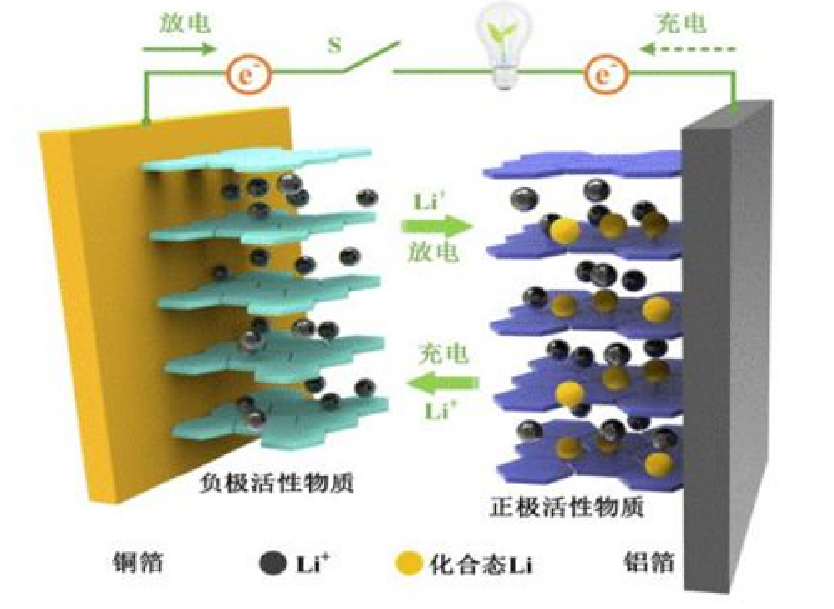

Battery aluminum foil is used as the collector of lithium-ion batteries. Usually, the lithium-ion battery industry uses rolled aluminum foil as the positive collector, which is also one of the basic raw materials for battery production.

In recent years, with the development of lithium-ion batteries, aluminum foil has been applied to the positive current collector, the core component of lithium batteries, because of its good conductivity. Aluminum foil is used as the positive electrode and copper foil as the negative electrode of lithium batteries, with aluminum foil accounting for 2-3% of the cost; In sodium batteries, because sodium does not react with aluminum, aluminum foil is used for both positive and negative electrodes, and the cost of aluminum foil accounts for about 5%. Due to the lower price, lower density and no need for charging and transportation of aluminum, the use of aluminum foil can reduce the cost, battery quality and transportation risk compared with copper foil.

Production process of battery aluminum foil

At present, there are two commonly used processing routes in the industry: ingot hot rolling method and the double roll casting rolling method. Hot rolling is to cast aluminum melt into flat ingots by semi-continuous casting method. Large metal ingots are hot rolled and cold rolled above their recrystallization temperature, and rolled into coils of a certain thickness as aluminum foil blanks; Casting rolling is to guide the aluminum melt through the casting nozzle between the two rollers with cooling water inside. The cooling water keeps flowing. The two constantly rotating rollers are used as crystallizers. The aluminum liquid is rolled to a certain thickness as a blank immediately after solidification. It only takes 2-3 seconds to complete the solidification and hot rolling processes in the casting rolling area.

In contrast, hot-rolled billets are generally of better quality and more suitable for rolling high-quality aluminum foil products. With technological progress, more and more enterprises use the twin roll casting method to produce battery aluminum foil billets. Twin roll casting and rolling method also has great advantages. Continuous casting and rolling has outstanding advantages in construction investment, process, energy consumption and other aspects, and can be matched with the electrolytic aluminum casting process. At present, the process level of aluminum foil blank production by casting and rolling is continuously improved, and the technical problem of reducing the thickness of battery aluminum foil from 15um to less than 8-10um is solved. This is also considered from both technical and economic aspects. More and more enterprises use cast rolling process as the production of battery foil blank, which provides a good prospect for the use of cast rolling method.

Battery foil alloy grades and common specifications

Main market for battery foil

Key performance requirements of battery foil

The aluminum calendering industry has high technical content, complex processes, and high equipment accuracy requirements. The aluminum foil processing process is the aluminum product with the most processing procedures, the least thickness, and the most difficult in the aluminum processing industry. The aluminum foil production process involves multiple complex rolling processes and heat treatment processes: aluminum alloy melting and casting, homogenization, casting and rolling, cold rolling, intermediate annealing, and foil rolling. There are technical difficulties in each link, and each link is closely linked and will have an impact on the final yield.

Battery foil has higher requirements than traditional aluminum foil. The thickness difference of battery aluminum foil shall be ± 3%, the surface quality shall be strict, the elongation shall be ≥ 3%, and the dyne value shall be ≥ 31; While the thickness difference of traditional aluminum foil is ≤± 5%, the surface requirement has no other quantitative requirements except the roller eye, the elongation is ≥ 1.5%, and the dyne value is 30.

Technical difficulties in battery foil production

The control of alloy blending and melting and casting process is more strict: the control of alloy impurities and how to improve the quality of aluminum foil through alloy blending are the first technical barriers in the industry. The performance of aluminum foil is adjusted by adding various trace elements during the melting process of aluminum ingot. Multiple technical indicators of battery foil have conflicting requirements for the alloy microstructure, and a certain proportion of adjustment is required. Therefore, the alloy deployment of battery foil requires rich experience in aluminum foil production. Through appropriate alloy composition and process design, the solid solution and precipitation amount are controlled, and the contradiction between work hardening and work softening is balanced, While maintaining high conductivity and high strength, it can improve the elongation of the current collector battery foil. The thickness of the battery foil is reduced, and defects such as bubbles and foreign impurities are exposed, so the control of the melting and casting process is very important.

Key quality requirements for battery foil

Quality system certification of battery foil

To enter the power vehicle battery industry, iatf16949 system certification is required; VDA6.3 system certification is also required to enter Korean, German and other foreign markets. Its fundamental purpose is to ensure customer satisfaction from meeting quality requirements, including product design, manufacturing, inspection and test according to customer requirements.

Focus: supplier management, customer requirements and expectations, defect prevention, process methods, continuous improvement, and establishment of index system.

Common defects of battery foil

Current capacity and project situation of battery aluminum foil

Since 2022, the production of domestic battery aluminum foil racing tracks has increased significantly:

-On January 7, Wanshun New Material disclosed its stock issuance plan to specific objects and proposed to raise no more than 1.7 billion yuan for the project of annual output of 100000 tons of power and energy storage battery foil and supplement working capital.

-On February 8, the annual output of 100000 tons of low-carbon high-end battery aluminum foil project of Dongyangguang started in Yidu City, Hubei Province;

-On April 6, the annual output of 100000 tons of double zero foil/battery foil project of Longding Aluminum started;

-On May 18, Lidao New Material announced to invest 1billion yuan to build a new energy battery collector project in Wuhe County, Anhui Province;

-On July 13, Tianshan Aluminum announced that it plans to invest 800million yuan in Shihezi, Xinjiang to build a production line with an annual capacity of 300000 tons of battery aluminum foil blanks; Invest 2billion yuan in Jiangyin to build a production line with an annual capacity of 200000 tons of battery aluminum foil finishing rolling, charcoal coating and slitting;

-On July 20, Dingsheng newly issued a fixed increase plan to raise 2.7 billion yuan, of which 1.9 billion yuan was used to build a project with an annual output of 800000 tons of battery foil and supporting blanks;

-On September 8, the annual output of 30000 tons of lithium battery materials project of Chalco new energy started, with a total investment of 459million yuan.

What is the incremental impact of resources on the battery foil market?

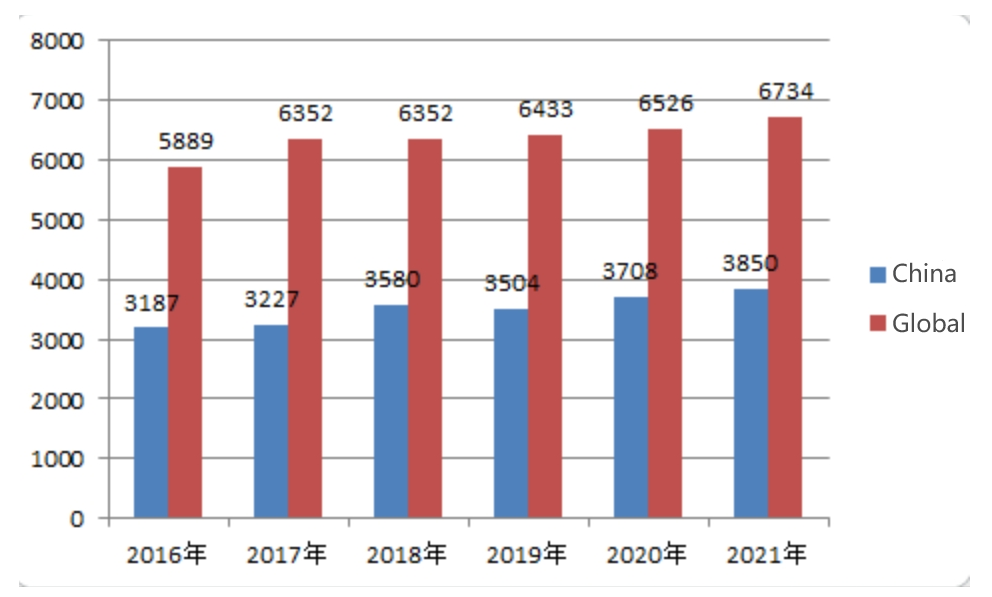

In 2021, the global electrolytic aluminum output was 67.34 million tons, an increase of 3.1%, and China's 38.5 million tons, an increase of 3.8%; The global aluminum processing output was 70.57 million tons, an increase of 6.1%, and China's 44.7 million tons, an increase of 6.2%; The difference should be completely supplemented by recycled aluminum? Among the existing aluminum products, how many products can be produced with recycled aluminum?

Among the enterprises that have announced the new battery foil project, most of them are only involved in the construction of aluminum foil mill. Only a few enterprises such as Dingsheng new material and Wanshun new material are built according to the industrial chain of "melting casting + cold rolling + foil rolling". Where do the blanks come from?

Some provinces have unwritten regulations that electrolytic aluminum cannot be sold out of the province, and must be sold in the form of aluminum processed materials across provinces. For example, a Western Province even made it clear that the added value of aluminum processed materials sold across provinces should not be less than 1500 yuan / ton.

To sum up, the source of the future increment of the battery foil industry is also the key. Without raw aluminum and billets, no more rolling mills are useless.

Future research and development direction of battery foil

Requirements for thickness of aluminum foil for lithium batteries with the rapid development of lithium batteries in recent years, we all hope that the energy density of batteries will be as high as possible and the weight of batteries will become lighter and lighter. The most important thing in the current collector is to reduce the thickness and weight of the current collector, so as to intuitively reduce the volume and weight of batteries. The positive aluminum foil has decreased from 15-20um in previous years to 13um, and then to 12um. Now many battery manufacturers have mass produced 9-10um aluminum foil. The future development direction is to continue to reduce the thickness, and there may be 6um battery foil products.

Aluminum foils developed in the early morning are mainly pure aluminum, such as 1070, 1235, 1100 and other alloys. In order to improve the energy density of the battery in the future, it is necessary to improve the tensile strength and elongation of aluminum foil while reducing its thickness. Therefore, developing diversified and high-strength alloys is the main direction in the future.

Future trend of battery aluminum foil in TW Era

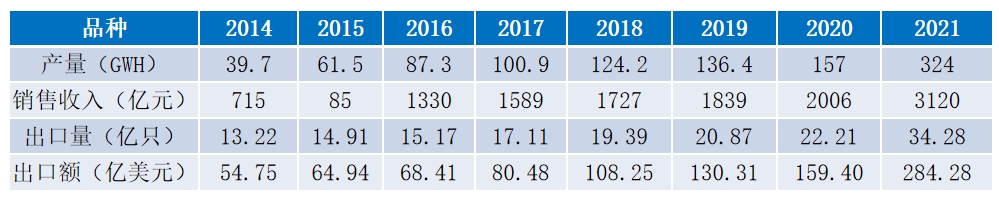

According to the statistical analysis of industry data, the total output of lithium-ion batteries in China in 2021 was 324gwh, an increase of 106% year on year in 2020. Among them, the shipment of power batteries in 2021 was 220gwh, accounting for 68%; The shipment of battery foil for electronic consumer products reached 72gwh, accounting for 22.2%; The shipment volume of energy storage battery foil products was 32gwh, accounting for 9.8%.

According to industry data, in the first half of 2022, domestic power battery shipments exceeded 200gwh, with a year-on-year increase of more than 150%. According to the calculation that 450 tons of aluminum foil are used for 1GWh power batteries, the domestic power battery aluminum foil shipments in the first half of the year exceeded 90000 tons, and the annual shipments are expected to exceed 200000 tons. If the shipments of electronic consumer and energy storage battery foil are added, the expected shipments this year are between 270000 and 280000 tons. According to industry forecasts, global power battery shipments will exceed 1550gwh and energy storage battery shipments will reach 416gwh by 2025. If the demand of light vehicles, low-speed vehicles, heavy trucks, ships and other scenarios are superimposed, the total global demand for lithium batteries is expected to exceed 2twh in 2025. This will drive the market demand of aluminum foil to 1-1.4 million tons.

On the other hand, since 2022, the industrialization process of domestic sodium-ion batteries has been significantly accelerated, and many battery and material enterprises have announced breakthroughs in the R&D and mass production of sodium-ion batteries, sodium ion cathode, electrolyte and other materials. Since aluminum foil is used as a collector for both positive and negative electrodes of sodium ion, the consumption is doubled compared with that of lithium batteries, which means that large-scale commercialization of sodium ion batteries will soon come. At the same time, the rapid explosion of the energy storage industry will also work at the same time. According to relevant data statistics, in 2021, China added 146 new energy storage projects, including 5 pumped storage projects, 131 electrochemical energy storage projects, and 120 lithium-ion battery energy storage projects among the electrochemical energy storage projects, which will provide growth impetus for further growth of aluminum foil market demand.

Correspondingly, the expansion pace and capacity of the battery aluminum foil industry cannot match the expansion scale and market demand growth of power batteries. In addition, due to the technical process, yield level, dependence on imports of core production equipment and long delivery cycle, the new capacity of the aluminum foil industry is released slowly.

In this case, power battery enterprises began to strengthen the supply guarantee of aluminum foil, while the head battery enterprises' demand for ensuring the stable supply of aluminum foil is more urgent.

-In December 2021, Ningde Times signed a long-term order agreement with Dingsheng New Material, and planned to purchase a total of 512000 tons of power battery aluminum foil from Dingsheng New Material and its subsidiary Wuxing Aluminum from November 1, 2021 to December 31, 2025.

-In June 2022, Honeycomb Energy signed a cooperation framework agreement with Dingsheng's new material. From 2022 to 2025, Honeycomb Energy purchased lithium battery aluminum foil and lithium battery carbon-coated aluminum foil from five-star aluminum, and the total purchase volume is expected to be 80800 tons.

-In August, Yunnan Aluminum Corporation said that its wholly-owned subsidiary Yunnan Haoxin had established a purchase and sales business relationship with Ningde Times for aluminum foil products for batteries.

Huabei Aluminum New Material, a subsidiary of Huabei Aluminum, has obtained strategic investments from four battery companies, Ningde Times (through its industrial fund Yibin Chendao), Hefei GuoXuan, Yiwei lithium energy and BYD, holding 10%, 10%, 7%, and 2.9% respectively.

Under the huge deterministic market demand, the battery aluminum foil race track is heating up rapidly, including Dingsheng new material, Wanshun new material, Yongjie new material, Xiashun aluminum foil, Huabei aluminum, Tianshan aluminum, Nanshan aluminum, Changyang aluminum, Shenhuo, Huafeng aluminum, Mingtai aluminum, Yunnan Aluminum, Dongyangguang, Longding aluminum and other enterprises are actively expanding the production capacity of battery aluminum foil.

It can be predicted that with the gradual release of new production capacity of aluminum foil, the proportion of power battery consumption continues, the proportion of demand for aluminum foil for energy storage batteries increases, and the industrialization of sodium ion batteries increases, the supply and demand relationship of battery aluminum foil market will gradually change in the future. However, due to the long construction cycle of aluminum foil project, long certification time, large technical gap between industries and difficulties in changing production, it is expected that it will be difficult to release a large number of new production capacity in the next 2-3 years, and the supply will remain tight.

In addition, there is a high technical threshold for battery aluminum foil. The technical indicators in tensile strength, elongation, conductivity, surface end face quality, dyne value and other aspects are relatively high. Superimposed on factors such as the scarcity of technicians, fast new product iteration and so on, the competition barrier of this industry is high, which will also boost the market concentration of battery aluminum foil to a certain extent.