b

Thank You!

Your requirement has been sent, we will contact you quickly!

Sent Failed!

Try again!

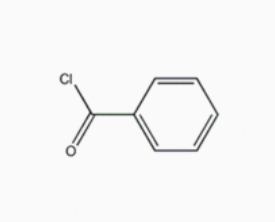

SynonymsBenzoyl: chloride 99.5+ % for analysis; Benzoil chloride; 4-Chlorocarbonylpolystyrene; alpha-chloro-benzaldehyd; O-Chloroformylbenzene

Molecular Formula:C7H5ClO

Molecular Weight :140.56

CAS:98-88-4

EINECS:202-710-8

Density:1.2188

Melting point:-1℃

Boiling point:198℃

Refractive index:1.552-1.554

Flash point:68℃

Water: solubilityreacts

Molecular Structure:

Benzoyl Chloride Purpose

Benzoyl chloride is used in organic synthesis, dyes and pharmaceutical raw materials, and in the manufacture of initiator benzoyl peroxide, tert butyl benzoate peroxide, pesticides and herbicides. In terms of pesticides, it is a new induced insecticide, which is an intermediate of isoxation (karphos). Benzoyl chloride is an important benzoylation and benzylation reagent. Most benzoyl chloride is used to produce benzoyl peroxide, followed by important chemical raw materials such as benzophenone, benzyl benzoate, benzylcellulose and benzamide. Benzoyl peroxide is used as polymerization initiator of plastic monomer, catalyst for polyester, epoxy and acrylic resin production, self coagulant of glass fiber materials, cross-linking agent of silicone fluororubber, oil refining, flour bleaching, fiber decolorization, etc. There are more than 20 original benzoyl chloride production enterprises in China, and some benzoic acid manufacturers also produce benzoyl chloride, with a production capacity of 10000 tons. However, according to the survey in 2003, due to the low profit of using the route with low pollution, and the restriction of the government on using the route with high pollution, and the rise in the price of raw materials, most manufacturers stopped production. In addition, benzoic acid can also react with benzoyl chloride to produce benzoic anhydride. Benzoic anhydride is mainly used as acylating agent, as a component of bleaching agent and flux, and can also be used to prepare benzoyl peroxide.

Benzoyl chloride is an important intermediate for the preparation of dyes, spices, organic peroxides, drugs and resins. Benzoyl chloride is also used in photography and the production of artificial tannins. It has also been used as an irritant gas in chemical warfare.

Health hazards

Invasion route: inhalation, ingestion and percutaneous absorption.

Health hazard: strong irritation to eyes, skin, mucous membrane and respiratory tract. Inhalation may cause death due to spasm, edema, inflammation, chemical pneumonia and pulmonary edema of larynx and bronchus. Poisoning symptoms include burning sensation, cough, wheezing, laryngitis, shortness of breath, headache, nausea and vomiting.

Toxicological data and environmental behavior

1. Acute toxicity

LD50: 1900mg / kg (rat oral); 790mg / kg (rabbit percutaneous)

LC50: 1870mg / m3 (inhalation in rats, 2h)

2. No data on irritation

3. Mutagenicity: Salmonella typhimurium 1 μ Mol / dish.

4. Carcinogenicity

IARC: insufficient evidence of carcinogenicity to animals and human 3.

Acute toxicity: lc501870mg / m3, 2h (rat inhalation)

Subacute and chronic toxicity: human inhalation 2ppm × In January, the lowest concentration causing stimulation.

Hazard characteristics: in case of open fire, high heat or contact with oxidant, there is a risk of combustion and explosion. React with water to generate heat and release toxic corrosive gas. Corrosive.

1、 Leakage emergency treatment

Evacuate the personnel in the leakage contaminated area to the safe area, and prohibit irrelevant personnel from entering the contaminated area. It is recommended that the emergency treatment personnel wear self-contained breathing apparatus and chemical protective clothing. Do not directly contact the leakage and stop the leakage under the condition of ensuring safety. Spray water to slow down volatilization (or diffusion), but do not spray water directly on the leakage or leakage point. Do not let the leakage come into contact with combustible substances (wood, paper, oil, etc.), absorb it with sand, vermiculite or other inert materials, and then collect and transport it to the waste treatment site for disposal. Large amount of leakage: it is better to remove it under the guidance of technicians without water treatment.

2、 Protective measures

Respiratory protection: gas mask must be worn when it may be exposed to its vapor or smoke. Wear self-contained breathing apparatus in case of emergency.

Eye protection: wear chemical safety glasses.

Protective clothing: wear work clothes (made of anti-corrosion materials).

Hand protection: wear rubber gloves.

Others: shower and change clothes after work. Store clothes contaminated by poisons separately and reuse them after washing. Keep good hygiene habits.

First aid measures

Skin contact: take off contaminated clothes and wash thoroughly with soapy water and clean water. In case of burns, seek medical treatment.

Eye contact: lift the eyelids immediately and rinse with flowing water or normal saline for at least 15 minutes. See a doctor.

Inhalation: quickly leave the site to a place with fresh air. Keep the respiratory tract unobstructed. Artificial respiration if necessary. See a doctor.

Ingestion: when the patient is awake, rinse his mouth immediately and drink milk or egg white. See a doctor.

Fire extinguishing method: dry powder, sand, carbon dioxide, foam. No water. [3]

Storage and transportation characteristics

[precautions for operation] closed operation, local exhaust. The operation shall be mechanized and automatic as far as possible. Operators must receive special training and strictly abide by the operating procedures. It is recommended that operators wear self-priming filter gas masks (full face masks), rubber acid and alkali resistant clothes and rubber acid and alkali resistant gloves. Keep away from kindling and heat sources. Smoking is strictly prohibited in the workplace. Use explosion-proof ventilation system and equipment. Avoid smoke. Prevent the release of smoke and vapor into the air of the workplace. Avoid contact with oxidants, alkalis and alcohols. Pay particular attention to avoid contact with water. Operate in nitrogen for disposal. Handle with care to prevent damage to packaging and containers. Fire fighting equipment and leakage emergency treatment equipment of corresponding varieties and quantities shall be provided. Empty containers may leave harmful substances.

[storage precautions] store in a cool, dry and well ventilated warehouse. Keep away from kindling and heat sources. The storage temperature shall not exceed 25 ℃, and the relative humidity shall not exceed 75%. Keep the container sealed. It shall be stored separately from oxidants, alkalis, alcohols and edible chemicals, and mixed storage shall not be allowed. Provide corresponding varieties and quantities of fire-fighting equipment. The storage area shall be equipped with leakage emergency treatment equipment and appropriate receiving materials. The "five pairs" management system of extremely toxic substances shall be strictly implemented.

Preparation method

Method 1: the preparation methods are as follows.

(1) Phosgene method

Benzoic acid is heated and melted, phosgene is introduced at 140 ~ 150 ℃, and a certain amount is introduced to reach the end point. Phosgene is driven out with nitrogen, and the tail gas is absorbed and destroyed. Finally, the product is obtained by vacuum distillation.

(2) Phosphorus trichloride process

Dissolve benzoic acid in toluene and other solvents, add phosphorus trichloride dropwise, react for several hours after dropping, distill to remove toluene, and then evaporate the finished product.

(3) Trichloromethylbenzene process

Toluene was chlorinated by side chain and then hydrolyzed to obtain the product.

Safety terminology

If you come into contact with your eyes accidentally, please immediately rinse with plenty of water and seek the advice of a doctor.

Wear appropriate protective clothing, gloves and goggles or masks.

In the event of an accident or discomfort, seek medical attention immediately (show the label if possible).