b

Thank You!

Your requirement has been sent, we will contact you quickly!

Sent Failed!

Try again!

Dicalcium Phosphate

Specification

Applicable preparation methods | Particle size distribution (95% distribution) | PH range |

Dry process and powder direct pressing | 20 ~ 120 mesh | 6~8 |

Wet granulation | Below 250 mesh | 6~8 |

*"Consistency evaluation of solid preparations" gives more opportunities to study anhydrous calcium hydrogen phosphate to cooperate with the R & D and industrial transformation of preparations.

*More suitable specifications and models have been developed and provided for the needs of the preparation.

Application in pharmaceutical preparation or preparation technology

◎ anhydrous calcium hydrogen phosphate can be used as an auxiliary material or as a calcium supplement. Because of its good compressibility and fluidity of coarse particles, it can also be used in pharmaceutical preparations.

◎ the compressibility and fluidity of coarse particles are excellent, which can be used for direct tablet pressing; The finer particles can be used in the classical wet granulation or rolling granulation.

◎ it is easy to change from laboratory to industrial production and application.

Excellent inorganic salt solid preparation diluent, absorbent and filler

◎ the main deformation mechanism of coarse granular anhydrous calcium hydrogen phosphate is brittle fracture, which reduces its strain sensitivity and is easier to change from laboratory to industrial application.

◎ partially neutralized stearic acid is added with 5 ~ 15 times aqueous liquid to form cream matrix

◎ superior adsorption can make oily substances and extracts powdered. It can be used as a filler and adhesive for traditional Chinese medicine tablets to adsorb more volatile oil and extract

Special uses and taboos of the product

◎ calcium phosphate salts have incompatibility with tetracycline. The surface of crushed anhydrous calcium hydrogen phosphate is alkaline, so it can not be used with drugs sensitive to alkaline PH.

◎ research shows that the surface acidity and alkalinity of crushed and non crushed anhydrous calcium hydrogen phosphate are different; The surface of non comminuted particles is acidic. This is of great significance to improve the stability of drugs, especially when the heavy pressing process is adopted, for example, from rolling to direct powder pressing, the particle size should be changed.

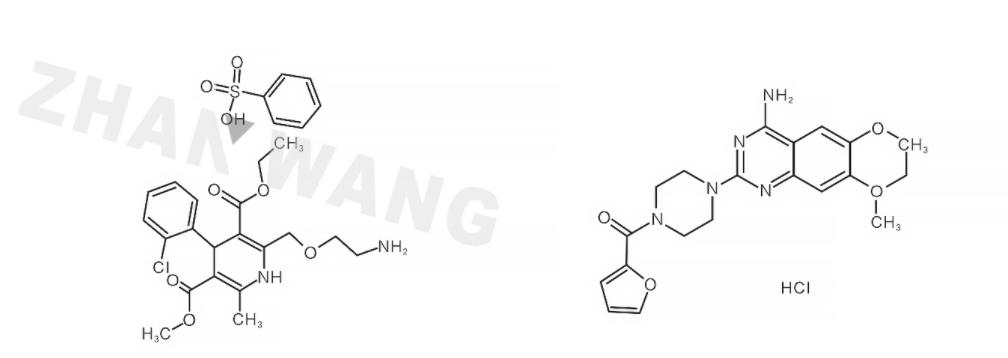

◎ the surface and internal pH of anhydrous calcium hydrogen phosphate prepared by different processes are different. At present, most dosage forms using anhydrous calcium hydrogen phosphate as filler have primary amino groups or nitrogen-containing heterocycles, as shown below: