b

Thank You!

Your requirement has been sent, we will contact you quickly!

Sent Failed!

Try again!

| Pallets Packing | 20'FCL | 40'FCL | ||

| With | Without | With | Without | |

|

25KG/Paper Bag

|

23.5 MT

|

20 MT

|

28 MT

|

--

|

|

25KG/Woven Bag

|

23.5 MT

|

20 MT

|

28 MT

|

--

|

We are exporter of large titanium dioxide manufacturer in China, Our titanium dioxide is produced by the third generation chlorinated hydrochloric acid extraction process. Compared with the sulfuric acid process, higher TiO2 content, less environmental pollution and low production cost.

Product Name: | Titanium Dioxide / Rutile TiO2 | CAS No.: | 13463-67-7 |

MF: | O2Ti; TiO2 | EINECS No.: | 236-675-5 |

Other Names: | Rutile Titanium Dioxide; TiO2 Powder; Titania; Titanium White; Rutile TiO2; Titanium White Pigment; | Medium Particle Size: | 0.25 Um |

TiO2 Contents: | 93% or 98% | MOQ: | 1000 KG |

Type: | White Pigment; Colorant; Inorganic pigments; | Appearance: | White Powder |

Grade Standard: | Tech Grade; Food Grade; | Sample: | Free |

Place of Origin: | Hainan, China | Rutile Crystal Content: | 99% Min |

Application: | titanium white pigment can be used in coatings, inks, plastics, rubber, paper making, cosmetics, chemical fiber and other industries. | ||

200000 Metric Tons per Year

Packaging Details: | 25 KG / Bag |

Port: | Xiamen Port, or other main ports in China |

Lead time: | In Stock |

Hainan Tangcai Technology Co., Ltd. is agent of large titanium dioxide manufacturing company in China. Relying on the production capacity and technical advantages of China TiO2, our agent titanium dioxide, pearlescent powder and color masterbatch are exported to more than 50 countries in the world, and gradually grow into China's leading titanium dioxide supplier. Hainan Tangcai Technology focuses on customer concerns and needs, provide more competitive services and commodities, and continues to create maximum value for the supply chain and industrial chain.

Our cooperative factory has perfect research and development, quality assurance, application and other centers, uses full-automatic and artificial intelligence + industrial Internet to implement the whole process of unmanned process, and has successfully developed hydrochloric acid extraction process and technology to produce high-quality chlorinated titanium dioxide and iron oxide.

This technology has the advantages of stability, low energy consumption, low emissions, recyclability, sustainability, safety and environmental protection, leading the industry to make disruptive and revolutionary technological progress. It is the world's exclusive independent research and development and the first technological process and has obtained authoritative certification and dozens of invention patents.

▶ We are an international trading company, specializing in the trading of titanium dioxide.

▶ Our cooperative factory adopts the world's first third-generation extraction chlorination process to produce titanium dioxide that is with almost no solid waste, low energy consumption, and environmental protection.

▶ Following the business philosophy of high quality and sustainable development, Tangcai Technology explores and discovers that focuses on customer concerns and needs, provide more competitive services and commodities, and continues to create maximum value for the supply chain and industrial chain.

Our titanium dioxide adopts the world's first third-generation extraction chlorination process to produce titanium dioxide, which is recycled throughout the industry, with almost no solid waste, low energy consumption, and environmental protection and sustainable development. We are the first titanium dioxide manufacturer to apply this production process in China.

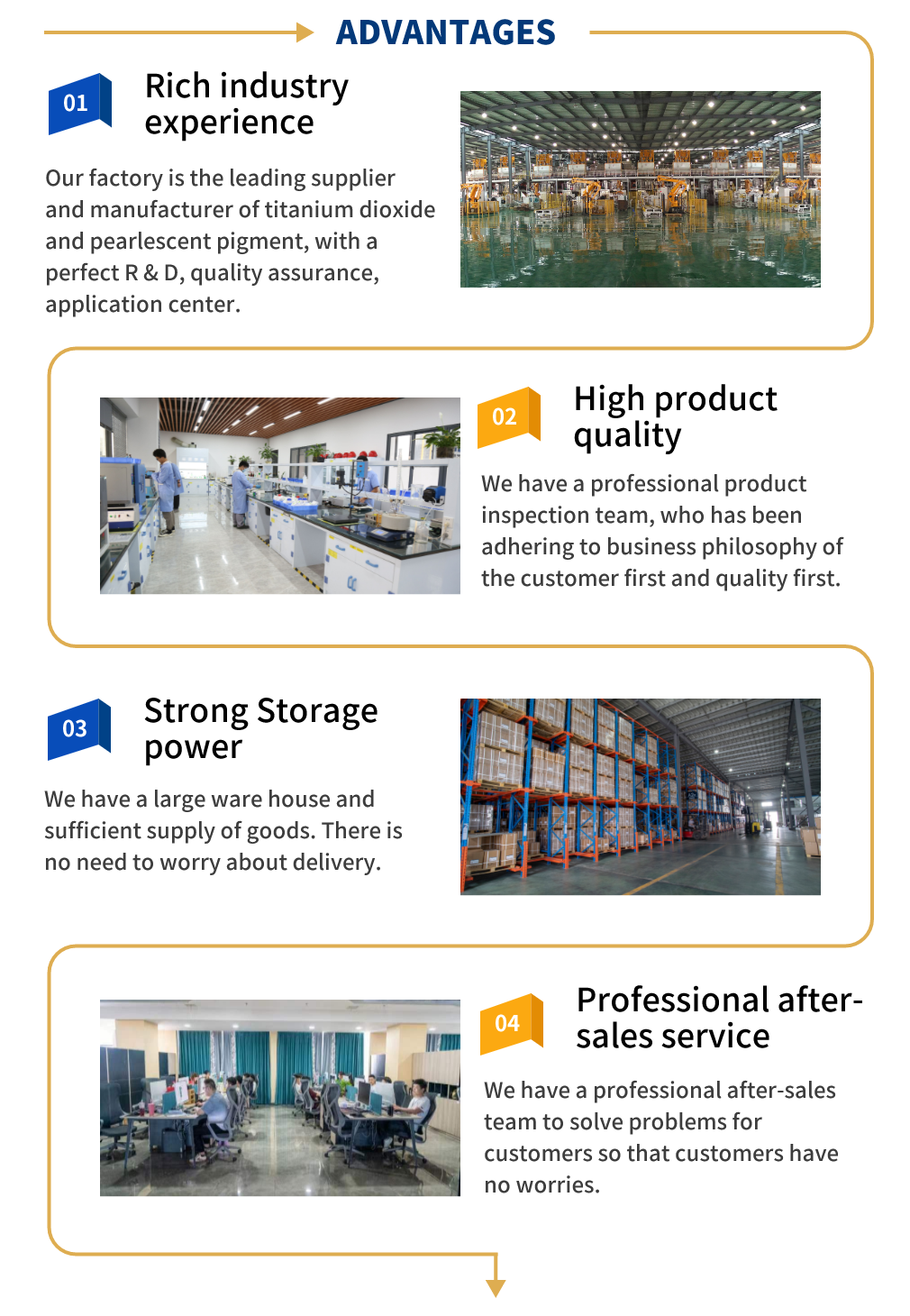

1. Application of titanium dioxide in coating industry

In all applications of pigment titanium dioxide, the amount of coating is the largest. Titanium dioxide is widely used in coatings, such as buildings, automobiles, ships, furniture, household appliances, coil coating, toys and daily necessities. In the coating industry, architectural coatings consume the most titanium dioxide, followed by coatings for automobiles, ships, railway vehicles and furniture. Because rutile titanium dioxide has better performance than anatase titanium dioxide, rutile titanium dioxide is selected as high weatherability coating for outdoor use of ships, bridges, automobiles, buildings and so on. At present, rutile titanium dioxide has exceeded that of titanium dioxide used in coatings. With the development of China's automobile industry and construction industry, the coating industry not only needs more titanium dioxide in quantity, but also has higher requirements for variety and quality.

2. Application of titanium dioxide in plastic industry

The plastic industry is the second largest user of titanium dioxide. In order to make plastics have beautiful colors, a certain amount of pigments are often added to plastics. Titania is required that the added pigments are easy to stain and disperse during the processing, and do not react with other components in the plastic. Because titanium dioxide has the characteristics of high whiteness, strong achromatic power, large hiding power and good chemical stability, adding titanium dioxide to plastic can improve the heat resistance, light resistance and weather resistance of plastic products, improve the physical and chemical properties of plastic products, enhance the mechanical strength of products and prolong the service life.

3. Application of titanium dioxide in papermaking industry

Titanium dioxide is mainly used as filler in paper industry. Titanium dioxide for papermaking generally uses anatase titanium dioxide without surface treatment, which can play the role of fluorescent brightener and increase the whiteness of paper. However, the laminated paper requires the use of rutile titanium dioxide with surface treatment to meet the requirements of light resistance and heat resistance. Because titanium dioxide has high refractive index and achromatic power, adding titanium dioxide to pulp can make the paper have better whiteness, higher opacity, good gloss, high strength, thin and smooth, non penetration during printing, and light weight.

4. Application of titanium dioxide in chemical fiber industry

Titanium dioxide is mainly used as a matting agent in the chemical fiber industry. Titanium dioxide has high refractive index, strong coloring power, large hiding power, good dispersion, high whiteness, fine and uniform particles, good chemical stability, not easy to change, does not affect the tension and dyeing of fibers, and has good light resistance and weather resistance. Titania is an excellent matting agent. Although the refractive index of rutile titanium dioxide is higher than that of anatase titanium dioxide, its atomic arrangement is dense, its hardness is greater than that of anatase titanium dioxide, and titania is easy to wear spinnerets and wire cutters. Therefore, anatase titanium dioxide without surface treatment is usually used as the matting agent of chemical fibers. Only when some special varieties in order to reduce the photochemical effect of titanium dioxide and avoid the degradation of fibers under the photocatalysis of titanium dioxide, the surface treated titanium dioxide is used.

5. Application of titanium dioxide in ink industry

Titanium dioxide has the characteristics of good whiteness, small and uniform particle size, high refractive index, high coloring power and hiding power, good physical and chemical stability, light diffusion, light resistance, heat resistance, weather resistance and hydrophobicity, which make titania not only an indispensable white pigment in ink manufacturing, but also a necessary raw material for blending many intermediate color ink products. The ink containing titanium dioxide is durable, does not change color, has good surface wettability, and is easy to disperse. Titania used in the ink industry has rutile type and anatase type.

6. Application of titanium dioxide in rubber industry

Titanium dioxide is not only used as a colorant in the rubber industry, but also has the functions of filling, anti-aging, acid and alkali resistance and reinforcement. When titanium dioxide is added to white and light colored rubber products, the finished products have the characteristics of slow aging, high strength, no cracking, no fading, large elongation and acid and alkali resistance. Titania for rubber is mainly used in automobile tires, rubber shoes, rubber floors, gloves, sports equipment, etc. Titania is generally anatase type. However, when used in the production of automobile tires, a certain amount of rutile products are often added in order to enhance its ozone and ultraviolet resistance.

7. Application of titanium dioxide in electronic industry

Titanium dioxide in the electronic industry is mainly used to manufacture ceramic capacitors, piezoelectric ceramics, transparent electro-optic ceramics and other electronic components required for electronic ceramic materials, one of the important raw materials. Titanium dioxide for electronic ceramics requires fine particles, large specific surface area, high reduction resistance, high dielectric constant and resistance, high purity and less impurities. Therefore, titania for capacitors or reagents is usually used in the electronic industry.

8. Application of titanium dioxide in food and pharmaceutical industry

Using the opacity of titanium dioxide can improve the decorative effect of food and pharmaceutical products. In addition to excellent pigment properties, titanium dioxide for food and medicine has very strict requirements for purity and harmful impurity content.

9. Application of titanium dioxide in enamel industry

Enamel is a product obtained by painting a layer of enamel on the metal embryo and then melting. The glaze must have opacification. Titanium dioxide is the strongest opacifier in the glaze. The glaze made of titania has strong transparency, light weight, strong impact resistance, good mechanical properties, bright colors, and is not easy to be polluted.

10. Application of titanium dioxide in welding electrode industry

The electrode is composed of welding core and coating. Titanium dioxide is one of the main raw materials of electrode industry. Titanium dioxide, as the most important raw material in the coating, is not only a good slagging agent, diluent, deoxidizer, but also an excellent viscoplastic agent and arc stabilizer.

The electrode with titania as coating can be used for both AC and DC, and has the characteristics of fast arc ignition, stable arc, no splashing, low melting point of slag, low viscosity, good fluidity, easy slag removal after welding, beautiful weld and good mechanical properties.

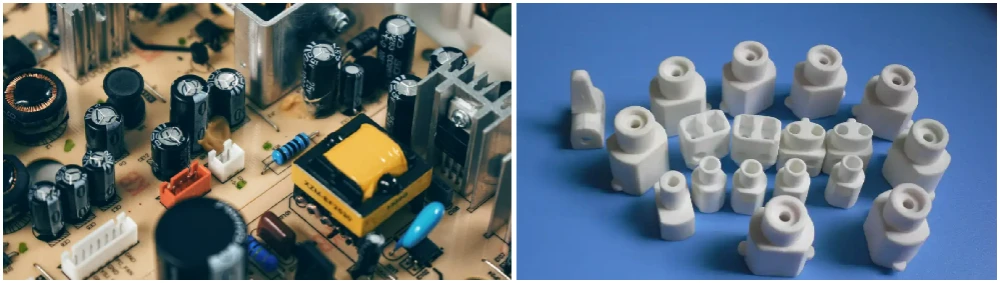

11. Application of titanium dioxide in photocatalysis industry

As a durable photocatalyst, titanium dioxide has been applied to the treatment of dye wastewater, pesticide wastewater, wastewater containing surfactants, oily wastewater, papermaking wastewater, etc. Titania has also been widely studied and applied in various environmental treatment issues such as antibacterial, deodorization, treatment of heavy metal ions, waste gas treatment, air purification, catalytic decomposition of water, etc. Titania can also be used as a carrier for a variety of catalysts, Some catalysts using titania as the carrier can improve the catalytic efficiency while reducing the active components.

12. Application of titanium dioxide in solar cell industry

The application research of titanium dioxide in solar cells is actually one of the two major directions of photocatalysis Research (solar energy conversion catalysis and environmental photocatalysis). Nano titanium dioxide is widely used in dye-sensitized, quantum dots, perovskite and other solar cells because of its suitable band gap, good photochemical stability, simple manufacturing process and other characteristics.

High quality, excellent quality, pollution-free, sustainable development.

The refractive index of titanium dioxide is the largest among white pigments, and the hiding power is the best. The refractive index of the rutile type is larger than that of the anatase type, so the rutile type is better than the anatase type.

Tinting power is an important characteristic index of titanium dioxide after titanium dioxide is mixed with another pigment. the ability of the mixture to display its own pigment can be obtained.

Oil absorption is also one of the most important pigment properties of titanium dioxide because it relates to the filling state of titanium dioxide in the vehicle and can explain its dispersibility in the medium.

The main factors affecting the weather-resistance index of titanium dioxide are its chemical composition and the chemical form of the coating material. Crystal structure application formula and so on.

Titanium dioxide manufacturer, rutile titanium dioxide powder, rutile TiO2; rutile titanium dioxide; titania TiO2; China TiO2; titanium dioxide pigment; titanium dioxide suppliers; China TiO2 suppliers; titanium dioxide food grade; titanium white pigment; titanium dioxide powder; China titanium dioxide; rutile anatase tio2;

TT, LC, OA, and DA, all the payments are optional, with the support of Chemball.

Please feel free to contact us and you will get free samples to test the quality before placing orders.

You are always warmly welcome to visit us at any time. Before we start B2B, Chemball has audited our company and approved our credit.

Contact us by Chemball page, email, mobile phone, any way you like! We will try our best to respond ASAP!