b

Thank You!

Your requirement has been sent, we will contact you quickly!

Sent Failed!

Try again!

CMC is used in the preparation of coating paper in the paper industry. It can be used as wet end additive, surface sizing agent and so on. The company's products have excellent water holding capacity, thickening capacity, suspension capacity and dispersion stability.

1. Application in coated paper

Control and adjust the rheology of the coating and the dispersion of the pigment to improve the solid content of the coating.

Enhance the water retention value of the coating and prevent the migration of adhesive in the coating, so as to improve the flatness of the coating and improve the coating quality.

Give the coating good stability and maintain the uniformity of the coating system.

It has good film-forming property and improves the gloss of the coating.

Improve the retention rate of brightener in coating and improve the whiteness of paper.

2. Application as wet end additive

It has good dispersion performance, which is conducive to paper forming and improve paper uniformity.

Improve the internal bonding force of fiber and improve the physical strength of paper.

Enhance sizing effect.

Improve the retention rate of various additives, fillers and fine fibers.

3. Application in surface sizing

Increase the roughening speed of paper products and improve the ink absorption performance of paper.

Good rheological and film-forming properties, enhance paper stiffness and smoothness.

Improve surface strength, air permeability and control curl.

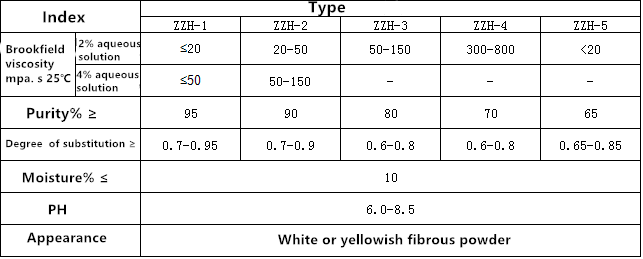

CMC model and main technical indexes for papermaking