Henan, China

Henan, China

Henan, China

Henan, China

Send Email

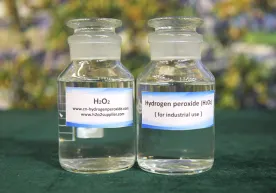

Hydrogen Peroxide / CAS 7722-84-1

OVERVIEW

Uses

- Sodium Chlorite Sodium Chlorite

- N-Methylmorpholine N-Oxide N-Methylmorpholine N-Oxide

- D-Tartaric Acid D-Tartaric Acid

- L(+)-Tartaric Acid L(+)-Tartaric Acid

- Potassium Bitartrate Potassium Bitartrate

- Potassium Sodium Tartrate Potassium Sodium Tartrate

- DL-Tartaric Acid DL-Tartaric Acid

- Sodium Pyroantimonate Sodium Pyroantimonate

- Dimethyl Sulfoxide Dimethyl Sulfoxide

- 3,4,5-Trifluorobromobezene 3,4,5-Trifluorobromobezene

- 3,4-Dimethoxybenzoic Acid 3,4-Dimethoxybenzoic Acid

- Lauryldimethylamine N-Oxide Lauryldimethylamine N-Oxide

- Caprolactam Caprolactam

- Benzoyl Peroxide Benzoyl Peroxide

- L-Threonic Acid Magnesium Salt L-Threonic Acid Magnesium Salt

- Magnesium,Peroxide###Magnesium Dioxide Magnesium,Peroxide###Magnesium Dioxide

- Calcium Peroxide Calcium Peroxide

- Sodium Percarbonate Sodium Percarbonate

- Sodium Perborate Sodium Perborate

- Polymaleicacidaq Polymaleicacidaq

- Polyoxirane-2,3-Dicarboxylic Acid Polyoxirane-2,3-Dicarboxylic Acid

- 2,6-Dibromo-4-Nitroaniline 2,6-Dibromo-4-Nitroaniline

- 4-Nitrobenzyl Alcohol 4-Nitrobenzyl Alcohol

- Ferric Sulfate Ferric Sulfate

- Sodium Perborate Monohydrate Sodium Perborate Monohydrate

Packaging

| Pallets Packing | 20'FCL | 40'FCL | ||

| With | Without | With | Without | |

|

1160 KG/IBC Drum

|

--

|

20.7 MT

|

--

|

20.7 MT

|

Lead Time

In Stock

Max Capacity

300000 MT/Year

REQUEST A QUOTATION

SubmitDESCRIPTION

CAS No.: 7722-84-1

Hydrogen peroxide content: 50%

Molecular formula: H2O2

Structural type:

Water solubility: miscible

Stability: slight instability

Storage conditions: the warehouse is ventilated, low-temperature and dry, and stored separately from fuel and organic matter

Food grade hydrogen peroxide is mainly used for bleaching, preservation and antisepsis of aquatic products, dried fruits and other foods. At the same time, it is also widely used in the sterilization of food production equipment and containers. It is widely used in dairy products, fruit juice drinks, Tetra Pak, Central Asia and other aseptic filling machine production lines.

Huize brand hydrogen peroxide is converted into hydrogen and oxygen after decomposition, without any pollution and side effects. And it has the characteristics of broad-spectrum sterilization, fast sterilization speed, no residue, no bubbles, non-toxic and harmless, good stability and so on. Our products are widely used in the food industry.

Food grade hydrogen peroxide can be widely used in the production and processing of dairy products, beverages, purified water, mineral water, beer, aquatic products, melons and fruits, meat products, bean products and other food products. Food grade hydrogen peroxide can destroy the protoplasm in microorganisms by using its strong oxidation ability of reactive oxygen species, so as to achieve the purpose of sterilization. The commonly used methods for disinfection with food grade hydrogen peroxide include spraying, washing, spray, soaking, wiping, etc.

The relationship between the quality of hydrogen peroxide and its application

Ordinary industrial grade hydrogen peroxide contains a lot of quinone organic impurities, heavy metals, arsenic, anions, mechanical impurities, etc., which seriously affect human life and health. For example, symptoms such as poisoning and cancer caused by organic substances. Recently, the media frequently exposed the bad events of some illegal manufacturers using industrial grade hydrogen peroxide bleach products and dried fruits.

High purity hydrogen peroxide is purified by a variety of special processes, removing a large number of toxic and harmful substances. It is a kind of high-quality and pure hydrogen peroxide, which guarantees people's health. Therefore, it can be widely used in the fields of food, electronics, chemical analysis and synthesis.

Usage of food grade hydrogen peroxide

Disinfection of production equipment

The sterilization effect can be achieved by fully washing the production equipment after diluting the food grade hydrogen peroxide water (purified water or tap water meeting the municipal requirements, the same below) 30-50 times.

Disinfection of pipes and packaging containers

Dilute the food grade hydrogen peroxide with water for 30-70 times, soak the pipe or container for about 30 minutes or rinse the pipe or container under pressure for 3-5 minutes, and then release the diluent.

Disinfection of production space

Dilute the food grade hydrogen peroxide 100 times and spray the diluent in the air with a spray to achieve the effect of sterilization.

Disinfection of personnel

After diluting food grade hydrogen peroxide 50-100 times, the hands, feet and skin of staff can be disinfected.

Using food grade hydrogen peroxide to disinfect different occasions and different items can adopt different methods and different concentrations according to different situations, which can achieve the ideal disinfection effect and reduce the cost.

The role of food grade hydrogen peroxide in the production and processing of various foods

In the processing of aquatic products, aquatic foods, dried fruits, meat products, etc., food grade hydrogen peroxide can be used as a processing aid for disinfection, preservation, corrosion prevention, bleaching, etc. Generally, the food grade hydrogen peroxide stock solution is directly used after being prepared to a concentration of about 3%, and then rinsed and rinsed with tap water after use; In order to avoid secondary pollution, you can wash with sterile water. The preparation method of sterile water: add food grade hydrogen peroxide in tap water at the ratio of 1:3000-5000, and stir it evenly.

Application of food grade hydrogen peroxide in dairy production

Milk is very sensitive to bacteria. The aseptic canning machine realizes the complete sterility of milk through the sterilization of food grade hydrogen peroxide. Because food grade hydrogen peroxide has the characteristics that other disinfection products do not have: normal temperature sterilization, broad-spectrum sterilization, fast sterilization speed, easy to decompose, and the decomposition products are water and oxygen, without any residue, and will not pollute the production environment of products and packaging boxes. There are two main sterilization methods of food grade hydrogen peroxide for dairy products: one is soaking method: heat the food grade hydrogen peroxide to a certain temperature and then sterilize the packaging box or packaging materials. This sterilization is generally carried out in the hydrogen peroxide tank. The other is spray method: the food grade hydrogen peroxide is evenly coated or sprayed on the surface of packaging materials, and then the hydrogen peroxide is completely evaporated by electric radiation heating or hot air heating, so as to complete the sterilization process.

Typical Properties

GET SAMPLE

Submit- Overview

- Descriptions

- Sample