Jilin, China

Jilin, China

Jilin, China

Jilin, China

Send Email

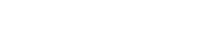

Diatomite-Condiment Filter Aid / CAS 61790-53-2

OVERVIEW

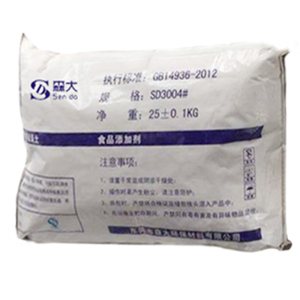

Packaging

20 KG/Woven Bag; 25 KG/Woven Bag

Lead Time

14-30 days

REQUEST A QUOTATION

SubmitDESCRIPTION

Diatomite-Condiment Filter Aid

Diatomite filtration is an efficient fine filtration process, which can filter out good water quality, small floor area and remove bacteria and algae. Diatomite is mainly used as filter aid. Diatomite powder products can filter out solid particles, suspended substances, colloidal particles and bacteria in the liquid, and play the role of filtering and purifying} liquid. Filter aids are mainly used in water purification and filtration of beer and medicine (for filtration of antibiotics, plasma, vitamins, synthetic medicine, injection, etc.), oil industry, organic solutions, coatings and dyes, alkalis, condiments, sugars, wines, etc.

① Monosodium glutamate, soy sauce, vinegar, enzyme preparation, citric acid, etc

For example:

Sterilization of soy sauce: there are many links in soy sauce production process and there is a great possibility of pollution. Generally, the finished products are sterilized by heating sterilization. The sterilization effect of single heating is unstable, which is easy to produce burnt taste and affect the taste of the product. At the same time, heating is also the loss of some beneficial components such as amino acids and reducing sugar. The use of Food Grade Diatomite filter aid to filter soy sauce not only does not lose the beneficial components of soy sauce, but also improves the product quality.

Senda diatomite - Functional filler - Physical and chemical indexes | |||

Item | Index | ||

Model | SD303# | SD307# | SD310# |

Grade | Flux roasted product | Flux roasted product | Flux roasted product |

Appearance | white | white | white |

Form | powder | powder | powder |

Drying reduction w/% | ≤3.0 | ≤3.0 | ≤3.0 |

Loss on ignition w/% | ≤0.50 | ≤0.50 | ≤0.50 |

Bulk density(g/cm3) | ≤0.65 | ≤0.65 | ≤0.65 |

PH(100g/L) | 8-11 | 8-11 | 8-11 |

Whiteness | 83 | 82 | 82 |

SiO2 w/% | ≥90 | ≥90 | ≥90 |

As (mg/kg) | ≤5 | ≤5 | ≤5 |

Pb (mg/kg) | ≤4 | ≤4 | ≤4 |

150 mesh sieve residue wt/% | 11.0 | - | - |

300 mesh sieve residue wt/% | - | - | - |

Median mesh | 200 | 120 | 100 |

Diatomite safety instructions

Hazard overview

Hazard category: diatomite is not applicable;

Invasion route: inhalation or dust contact with eyes.

Environmental hazards: diatomite is not applicable;

Fire and explosion hazard: diatomite is not applicable;

Health hazards: prolonged and frequent exposure to excessive concentrations of dust from this product (or any other dust hazard) may lead to chronic lung disease. Dust entering the eyes may cause temporary tingling or red eyes. This product has not been listed as a carcinogen by NTP or IARC.

First aid measures

Skin contact: not applicable

Eye contact: flush eyes with plenty of water. If the inflammation persists, consult your doctor.

Rain shall be prevented during transportation. It shall not be transported with contaminated, corrosive or sharp metal objects. It shall be handled with care during loading and unloading. It is not allowed to throw it directly from a high place or lift it with hard objects such as iron hooks, so as to ensure that the outer packaging is intact.

Precautions for diatomite storage

Storage conditions

During storage, the products shall be protected from rain, moisture, sun and corrosion. When stacking, the products shall not directly contact the ground. They shall be stacked on pallets or moisture-proof felt plates, and the stacking layer height shall not exceed 30 layers.

Product specification: 20kg / bag, 25kg / bag, ton bag

Product validity: 36 months

Precautions for transportation: prevent rain during transportation and do not transport with polluting, corrosive or sharp metal objects. Handle with care during loading and unloading. Do not throw it directly from height or lift it with hard objects such as iron hooks, so as to ensure that the outer packaging is intact.

Typical Properties

Auxiliary > Water Treatment Chemicals

Food(Feed) Additives > Other Food Additives

GET SAMPLE

Submit- Overview

- Descriptions

- Sample