On Chemball

My Chemball

+86-571-8627 3270

Henghe Materials & Science Technology Co., Ltd.

Henghe Materials & Science Technology Co., Ltd.

Main Products:

Hydrogenated Petroleum Resin / C5 Hydrocarbon Resin / C9 Hydrocarbon Resin / C5/C9 Copolymer Hydrocarbon Resin / Coumarone Resin / Dicyclopentadiene

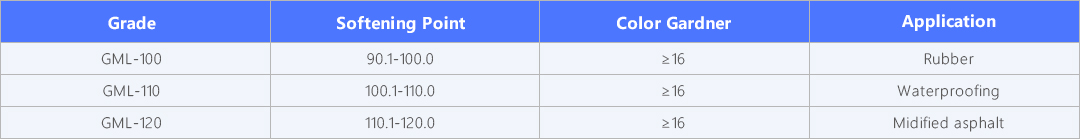

Coumarone Resin

- Overview

- Documents

- Descriptions

- Sample