Defoamer

Product introduction:

Dry powder defoamer has excellent defoaming ability, defoaming rate and good foam inhibition performance. It can be applied to neutral and alkaline systems, has good adaptability to cement-based and gypsum based mortar, and has good compatibility with various admixtures.

Product features:

·Less oil slick and good universality

·Strong adaptability to low temperature

·Fast defoaming rate and strong defoaming rate

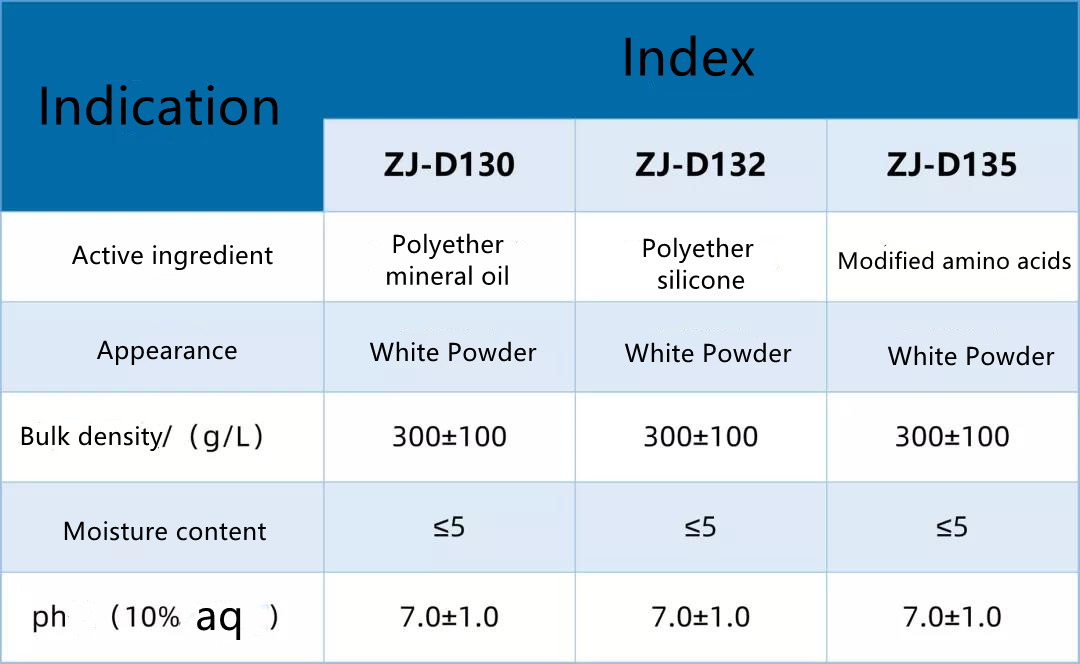

Product model & physical and chemical indexes:

Application scope:

Defoamer can be used in cement-based and gypsum based fluidity mortar or slurry, and d132 has better low-temperature adaptability. Specific application fields include: cement-based self leveling mortar, gypsum based self leveling mortar, grouting material, grouting material, repair mortar, waterproof mortar, waterproof coating, decorative mortar, prefabricated components, etc.

Usage method:

Add defoamer to the powder and mix evenly. According to the performance requirements and application effect, the recommended dosage is 0.05 ~ 0.2% of the total weight of dry mixture.

Packaging and storage:

This product is packed in 20kg paper plastic composite lined film bag. It should be stored in a cool place and protected from moisture. The storage time should not exceed 6 months.

Antifoaming agents refer to substances that can reduce the surface tension of water, solutions, suspensions, etc., prevent foam formation, or reduce or eliminate the original foam. During paper making, foam will accumulate in the wet paper system due to unreasonable sizing, poorly washed pulp, use of basic filler in acidic system, and addition of various additives, resulting in formation of foam spots on the paper that is copied, such as transcurtain and so on. Depending on the situation, various types of antifoam agents can be added in the paper manufacturing procedure. Antifoam agents in early use were hydrocarbon oils such as coal oil, paraffin oil, sulfonated oils, sodium oleate, octanol, and others. Among the effective components of the more recently used antifoam agents are silicones, polyether type surfactants, aliphatic amide type surfactants, etc. Antifoam agents can be further divided into oil-based and water-based antifoam agents, and their effective active components are generally the same, the advantage of water-based antifoam agents is that it has extremely little effect on various other additives, does not produce accumulation in the circulation, avoids the occurrence of resin barriers, and thus is the direction of development.