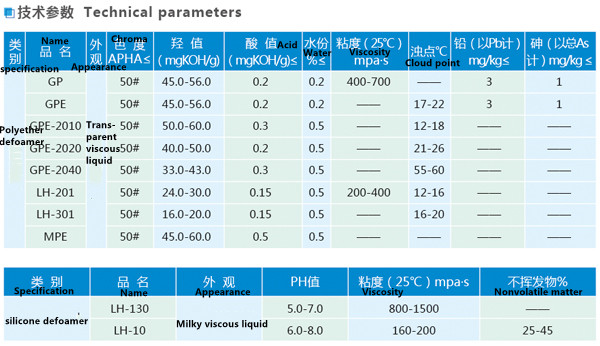

Polyether Defoamer\Silicone Defoamer

Product uses: eliminate foam formed in the process of production, widely used in the pharmaceutical industry, all kinds of antibiotics, monosodium glutamate, yeast, citric acid, itaconic acid, xanthan gum and other fermentation process to eliminate bubbles. It can also be used in chemical industry, textile, printing and dyeing, paint, coating, papermaking and other industries with remarkable results.

Antifoaming agents refer to substances that can reduce the surface tension of water, solutions, suspensions, etc., prevent foam formation, or reduce or eliminate the original foam. During paper making, foam will accumulate in the wet paper system due to unreasonable sizing, poorly washed pulp, use of basic filler in acidic system, and addition of various additives, resulting in formation of foam spots on the paper that is copied, such as transcurtain and so on. Depending on the situation, various types of antifoam agents can be added in the paper manufacturing procedure. Antifoam agents in early use were hydrocarbon oils such as coal oil, paraffin oil, sulfonated oils, sodium oleate, octanol, and others. Among the effective components of the more recently used antifoam agents are silicones, polyether type surfactants, aliphatic amide type surfactants, etc. Antifoam agents can be further divided into oil-based and water-based antifoam agents, and their effective active components are generally the same, the advantage of water-based antifoam agents is that it has extremely little effect on various other additives, does not produce accumulation in the circulation, avoids the occurrence of resin barriers, and thus is the direction of development.