b

Thank You!

Your requirement has been sent, we will contact you quickly!

Sent Failed!

Try again!

Polytetrahydrofuran (PTMEG) is a homopolymer obtained by cationic ring opening polymerization of monomer tetrahydrofuran (THF) in the presence of catalyst. It is a linear polyether glycol with primary hydroxyl end group. It is a white waxy solid at room temperature. When the temperature exceeds room temperature, it melts into a transparent and colorless liquid. It is easy to dissolve in alcohols, esters, ketones, aromatics and chlorinated hydrocarbons, but insoluble in ester hydrocarbons and water. PTMEG products are divided into 250, 650, 1000, 1400, 1800, 2000, 3000, etc. according to the relative molecular weight. In industrial production, the relative molecular weight can be adjusted according to the needs of the market, so as to produce products of different specifications. PTMEG is mainly used to produce polyurethane elastomer, polyurethane elastic fiber (spandex) and ester ether copolymer elastomer.

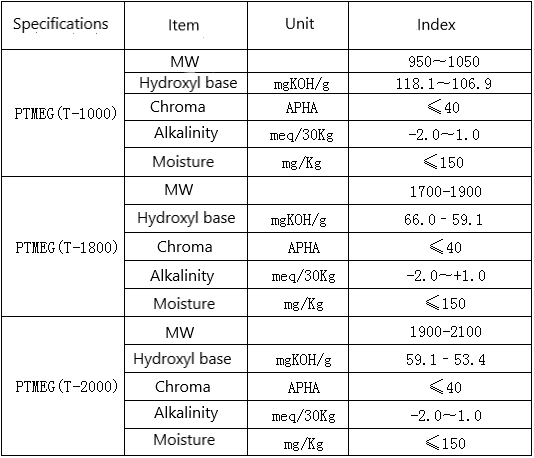

Quality index:

Product features:

Polytetrahydrofuran is produced with natural gas as raw material and heterogeneous catalyst process of American INVISTA company. The product quality is in a leading position in the world. In January 2013, it passed INVISTA PTMEG business qualification certification and became the first manufacturer in China to obtain INVISTA PTMEG technology license. Its products are used by Foshan INVISTA, Huafeng spandex and other enterprises and have been highly praised. The company can provide customers with high-quality 1000, 1800, 2000 and other molecular weight products.

Product purpose:

(1) It is mainly used to produce polyurethane elastomer, spandex and ester ether copolymer elastomer.

(2) Thermoplastic polyurethane produced with PTMEG as raw material is widely used in petrochemical, machinery, military industry, shipbuilding, automobile, synthetic leather and other industries.

(3) It is widely used in the production of coatings, surfactants and other products.

Storage and transportation conditions:

Tank cars, tank cars and ISO storage tanks can be used in bulk, all of which are insulated and equipped with heating coils.

Storage: under nitrogen condition; Do not store with strong inorganic oxidants (such as nitric acid); Prevent moisture absorption and keep the container closed; It is best to store at a temperature above 45 ℃ (113 ° f) to prevent curing.