Antioxidant

Other Auxiliary Agent

Petroleum Additives

Adsorbent

Water Treatment Chemicals

Rubber Additives

Adhesive Additives

Cross-Linking Agent

Flame Retardants

UV Absorbers

Organic Extractant

Resin Additives

Electronics Chemicals

Pesticide Additives

Building Chemicals

Plastic Additives

Oilfield Chemicals

Adhesive

Plastic Rubber Chemicals

Paper Additives

Molecular Sieve

Coating Additives

Textile Auxiliaries

Fluorescent Brightener

Polyethylene Glycol Derivatives

Coupling

Forest Chemicals

Leather Auxiliary Agents

Beneficiation Agents and Smelting Additives

Dye Auxiliaries

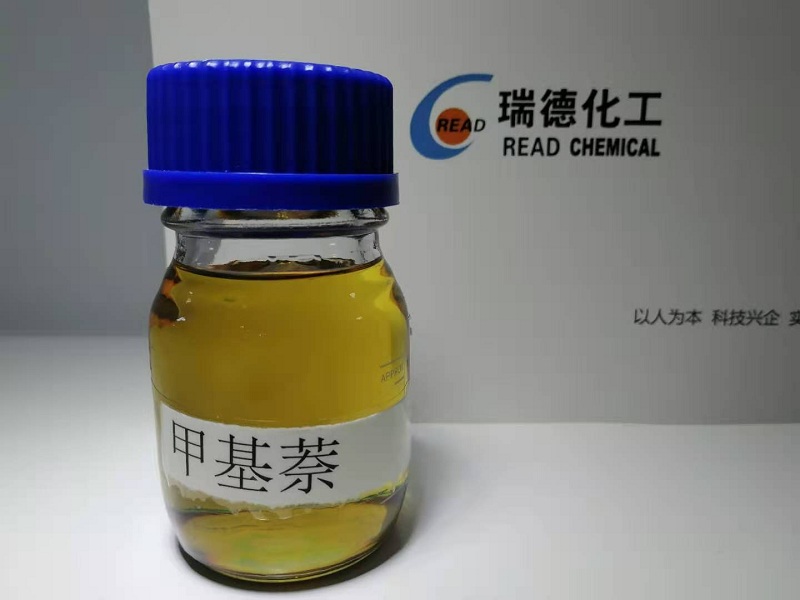

CAS:1321-94-4

Molecular Formula:C11H10

Alias

More Information

Mixed Methylnaphthalene; 1(Or2)-Methylnaphthalene; Naphthalene, Methyl-; Mix-Methylnaphthalene; Monomethylnaphthalene; 1-Methylnaphthalene; Alpha-Methylnaphthalene; Petroleum Methylnaphthalene

Brief Introduction

Methylnaphthalene is the main raw material for the production of disperse dye auxiliaries (dispersants). It can also be used as heat carrier and solvent, surfactant and sulfur extractant. It can also be used to produce plasticizer and fiber dyeing aid. It can also be used as standard fuel for the determination of alkane number and cetane number.

Suppliers

View More Vendors (3) >

CAS:2439-35-2

Molecular Formula:C7H13NO2

Alias

More Information

2-(Dimethylamino)Ethyl Prop-2-Enoate; Dimethylaminoethyl Acrylate; DA; Dmaea; Adame; DAA; 2-Propenoic Acid, 2-(Dimethylamino)Ethyl Ester; Acrylic Acid 2-(Dimethylamino)Ethyl Ester; 2-Dimethylaminoethyl Prop-2-Enoate; 2-(Dimethylamino)Ethyl Acrylate; 2,2-Dimethylaminoethyl Acrylate; 2-(Acryloyloxy)Ethyldimethylamine; Acrylic Acid 2-(Dimethylamino)Ethyl; Propenoic Acid 2-(Dimethylamino)Ethyl Ester

Brief Introduction

2-dimethylaminoethyl acrylate appears as a colorless to light yellow liquid with an acrid odor. Insoluble in water and floats on water. Irritates the eyes and produces tears.

Suppliers

View More Vendors (3) >

CAS:112-35-6

Molecular Formula:C7H16O4

Alias

More Information

MTG; TGME; TEM; 2-(2-(2-Methoxyethoxy)Ethoxy)-Ethano; 2-[2-(2-Methoxyethoxy)Ethoxy]-Ethano; 3,6,9-Trioxa-1-Decanol; Tmat; Methoxytriethylene Glycol

Brief Introduction

This product is used as brake fluid and chemical raw materials.

Suppliers

View More Vendors (3) >

CAS:65996-62-5

Alias

More Information

Strke, Oxidiert; Starch, Oxidised; Starch, Bleached; Starch, Oxidized; 2-[2-[[3,4-Dihydroxy-6-(Hydroxymethyl)-5-Methoxyoxan-2-Yl]Oxymethyl]-6-[4,5-Dihydroxy-2-(Hydroxymethyl)-6-Methyloxan-3-Yl]Oxy-4,5-Dihydroxyoxan-3-Yl]Oxy-4-Hydroxy-6-(Hydroxymethyl)-5-Methoxyoxan-3-One; Modified Starch

Brief Introduction

Thickening agent; Emulsifier; Binder. It can be used as binder and starch jelly for surface seasoning of fried food. In bread production, it can improve gas holding capacity, shorten fermentation time and increase bread volume.

Suppliers

View More Vendors (3) >

CAS:9084-06-4

Molecular Formula:C21H14Na2O6S2

Alias

More Information

Naphthalenesulfonic Acid,Polymer With Formaldehyde,Sodium Salt; Sodium Salt Of Alkylnaphthalenesulfonate Formaldehyde Polymer; Formaldehyde-Naphthalenesulfonic Acid Condensate Sodium Salt; Sodium Naphthalene Sulfonate Formaldehyde Condensate; Dispersing Agent CNF; Diffusing Agent MF; Dispersant MF; Dispersant Agent MF

Brief Introduction

Dispersant MF is mainly used as dispersant and filler for vat dyes and disperse dyes. It is mainly used as processing agent and dispersant for the grinding of disperse dyes and vat dyes. Its performance is better than dispersant n. Dispersant MF has the advantages of good grinding effect, good dispersion, heat resistance and stable dispersion at high temperature. It is more resistant to high temperature and stable than dispersant n. Dispersant MF can make the dye bright, increase the color power and color evenly. Dispersant MF can also be compounded with various dispersants to meet the commercialization requirements of various disperse dyes and vat dyes; It can also be used as early strength water reducing agent for concrete; It can be used as dispersant for grinding vat dyes and dispersant for vat dye suspension dyeing; As well as latex stabilizer in rubber industry and tanning aid in leather industry.

Dispersant MF is mainly used as dispersant and filler for vat dyes and disperse dyes. It is mainly used as processing agent and dispersant for the grinding of disperse dyes and vat dyes. Its performance is better than dispersant n. Dispersant MF has the advantages of good grinding effect, good dispersion, heat resistance and stable dispersion at high temperature. It is more resistant to high temperature and stable than dispersant n. Dispersant MF can make the dye bright, increase the color power and color evenly. Dispersant MF can also be compounded with various dispersants to meet the commercialization requirements of various disperse dyes and vat dyes; It can also be used as early strength water reducing agent for concrete; It can be used as dispersant for grinding vat dyes and dispersant for vat dye suspension dyeing; As well as latex stabilizer in rubber industry and tanning aid in leather industry.

Suppliers

View More Vendors (3) >

Inquiry (

10

/ 10

)

Clear All

Sign In

Error!

![Sodium poly[(Naphthaleneformaldehyde)Sulfonate]](https://res.chemball.com/upload2/30f2d1ca-be6f-4583-b10f-c923ccb3448f.jpg)

![Sodium poly[(Naphthaleneformaldehyde)Sulfonate]](https://res.chemball.com/upload2/50671177-0b38-477f-bcd7-ee8e583951fa.png)

![Sodium poly[(Naphthaleneformaldehyde)Sulfonate]](https://res.chemball.com/upload2/07cd4880-00b6-4aa6-ab49-890c5e9964f4.png)